Exploring the Potential of Nano Materials for Wearable Devices: Inside Dewei Chu’s Lab

POSTED: 26 Sep, 2024

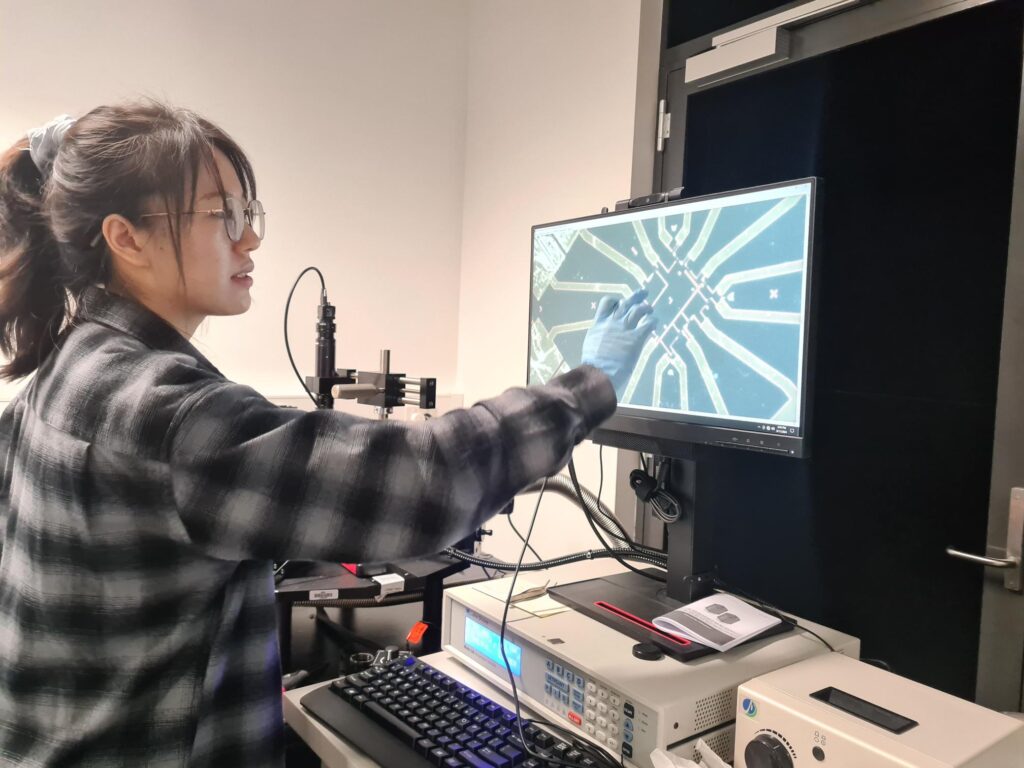

We caught up with Hub Chief Investigator Professor Dewei Chu at the Nanoionic Materials Group lab, based at UNSW Sydney, to learn about his group’s ongoing research.

Professor Chu is a recipient of the prestigious ARC Mid-Career Industry Fellowship. The fellowship enables Chu in partnership with industry to utilise his expertise and skills to address industry-specific challenges in powering IoT devices.

Chu’s research group consists of 36 members, including 26 students, and 10 postdocs. The lab, located at UNSW Hilmer Building, has been established for 9 years. Within the Hub Chu is currently collaborating with industry partners Australian Advanced Materials and Tiger Pharm supporting our mission to build an end-to-end ecosystem integrating sensor science, design, manufacturing and commercialisation capabilities.

The Nanoionic Materials Group

The Nanoionic Materials Group focuses on designing, synthesising, and printing nano (small) materials made of metal oxides and sulfides. These materials, such as self-powered batteries and supercapacitors, are used in wearable electronics and energy storage and conversion. The group’s ongoing research feeds into the Hub’s research themes: Biophysical Sensors (theme 1) and Energy and Data Management Solutions (theme 3).

What’s the group working on currently?

The increasing development of electronic devices like wearable sensors and flexible batteries has led to the exploration of high-quality, high-performance, and stable transparent and bendable materials for electrodes. Metal nanowire (NW) networks, have emerged as a promising option due to their electrical properties, flexibility, and abundance. Copper, in particular, stands out for being both effective and cost-efficient. However, some challenges remain, such as ensuring the stability and conductivity of copper nanowires. In a new study, aimed at providing guidance for designing strong metal nanowires for use in flexible and wearable applications, published in the Chemical Engineering Journal, Chu and his team developed, Cu@Ag core–shell NWs using a method called galvanic etching. This process enables the control of the structure of the silver coating by adjusting the amount of silver used. It showed an improved ability to withstand heat, keeping their conductivity even after being heated for several days.

The devices are more resistant to mechanical bending after surface modification due to the optimised NW junction. As a result, various human movements related to hand, elbow and knee can be easily detected by the sensors and Morse code, showcasing great promise for wearable sensors. They also conducted in vitro antibacterial tests to evaluate the performance of the devices. Bacterial infections are another big concern during the device operation, which may pose public health risks. A reliable antibacterial activity was achieved in the modified devices, which is attributed to the introduced Ag coating and improved stability.

As the demand for wearable devices continues to grow, Chu and his team’s diverse research holds great promise for the development of next-generation wearable devices. They continue exploring innovative concepts to engineer and create with nanomaterials.

Subscribe to the Hub’s newsletter.

Rational design of robust Cu@Ag core-shell nanowires for wearable electronics applications

https://doi.org/10.1016/j.cej.2024.154001